Machining Center Selection: Three Things to Know

Let’s face it: if you’re shopping for a CNC machining center, there are a number of good choices out there. And just like picking out your next car or a vacation home, there’s a lot to consider before buying one. Kent CNC recognizes this. We encourage our customers to educate themselves on what’s available, what to look for, and what options to select on your next one. Here are a few things to consider:

Identify your needs

No one has a crystal ball. Job shops in particular are at the mercy of their customers in terms of what materials they’ll be machining in a year or two, and the accuracies they’ll be expected to hold. How many RPM will you need if you get that big job next year? How many tools, and what about program storage? What control brand are your operators (or future operators) most familiar with? Do you need rigid tapping, additional M-codes, and user macros? Some of these may seem unnecessary now, but how about five years from now? Investing in the right machine configuration up front will not only provide the quickest ROI, but eliminate expensive field retrofits after the fact (or having to buy yet another machine).

Check the specs

Comparing one machine with another is a lot like asking which dog is best at the Westminster Dog Show. Unfortunately, this aspect of machine tool shopping is a necessary but time-consuming step. Once you’ve identified your requirements as mentioned in the previous section, put everything in a spreadsheet and start filling in the blanks. You might find that, by the time you’ve added in coolant through-the-spindle, a 4th-axis interface, air blast, and other features that some machine builders charge extra for, the price tag could be even higher than the popular Brand X you’ve been looking at.

Talk to others

There’s more than price to consider, however—there’s also uptime. Any sales representative worth his or her salt can introduce you to a number of satisfied customers you can speak with before purchasing a new machining center. Take the time to do this, and be sure to ask the tough questions: how long have they owned the machine? How many service calls has it had and why? What was the response time, and do they have any regrets? And of course, any reference customer should be doing similar work. If you’re machining titanium all day, what’s the point of talking to a shop that only cuts aluminum?

The Right Machining Center

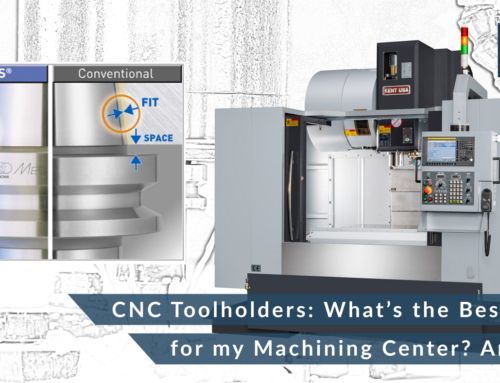

If you have wide-ranging requirements, consider a general-purpose machine tool like Kent CNC’s KVR-4020A CNC vertical machining center. Its roller-style linear guideways are known for their extreme precision. It offers fast traverse speeds, and year-after-year productivity in any machining environment. And its Meehanite FC-25 grade casting provides the highest level of dampening and stability no matter what you’re cutting.

Remember, even the lowest priced CNC lathe or machining center is going to put a sizable dent in any shop’s budget. Buyers can easily offset this expense with additional throughput. It’ll also be much easier to say “yes, of course” the next time a customer calls looking for parts. Happy shopping.