KLT Horizontal Turning Series

Product Highlights

The KENT USA KLT-2000 series CNC slant bed lathe combines proven machine design with advance technology in control and manufacturing. Reliability and stability make these a favorite among demanding job shops and in-house productions alike. The heavy duty turret and rigid machine body structure enable higher turning efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around. Upgrade your global competitiveness today.

8” 3-jaw chuck with 2” bar capacity

5” max turning diameter, 15.7” max turning length

45° slant bed with one piece Meehanite® casting for superior dampening and stability

High grade C3 precision ball screws and pretension for enhanced precision

Auto lubrication system metered check valves and piston distributor

| Specifications | KLT-2000 |

| Controller type | Fanuc 0i-TF |

| Swing over bed | 520 mm (20.5”) |

| Swing over saddle | 320 mm (12.6”) |

| Maximum turning diameter | 300 mm (11.8”) |

| Maximum turning length | 400 mm (15.7”) |

| Bed slant angle (box ways) | 45° |

| Spindle nose taper | A2-6 |

| Power chuck diameter | 8” |

| Spindle speed | 4500 rpm |

| Spindle motor power | 15 kW (20 hp) |

| Bar capacity | 51 mm (2”) |

| Z-axis travel | 400 mm (15.7”) |

| X-axis travel | 170 mm (6.69”) |

| Z-axis rapid feed rate | 30m/min (1181 ipm) |

| X-axis rapid feed rate | 30 m/min (1181 ipm) |

| Turret driven type | Hydraulic (Optional Servo) |

| Number of tool station | 8 (Optional 12) |

| Square shank tooling size | 25 mm |

| Round shank tooling size | 32 mm |

| Tail stock body travel | 200mm (7.87”) |

| Quill travel | 150 mm (5.9”) |

| Quill diameter | 70 mm (2.75”) |

| Quill taper | MT 4 |

| Quill control type | Hydraulic |

| Tail stock body positioning | Manual |

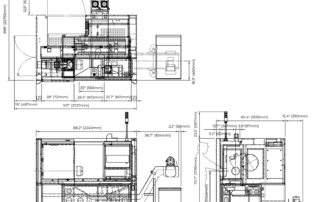

| Floor space (Length) | 3.2 m (126”) |

| Floor space (width) | 1.8 m (71”) |

| Floor space (height) | 2.3 m (91”) |

| Weight | 1500 kg (3300 lb) |

- Fanuc 0i-T CNC control with 10.4” color LCD

- Fanuc i-Series high torque spindle and axis motor with digital drive system

- Fanuc Auto-Measure System (X and Z)

- Fanuc Macro-B and High Speed Skip Function

- Fanuc USB, PCMCIA, Ethernet and RS-232 ports

- Fanuc Manual Guide i – computer assist programming

- Fanuc 400 registered part program numbers and 640M part program memory

- Swivel-Out control panel

- Heat exchanger for electrical cabinet

- Hydraulic power supply unit

- Flood coolant system (4 bar)

- Chain (Hinge) type chip conveyor and chip cart

- Full enclosure and way covers

- Automatic lubrication system

- 3 color stack indicator light

- 8 station heavy duty high precision turret (10/12 station optional)

- Standard soft jaws 3 sets + hard jaws 1 set

- Precision Linear Guideways on X and Z axis

- 45° slant bed with one piece Meehanite® casting

- C-3 grade high precision ball screws

- Facing tool holder (R/H) 25×25 mm 1 set

- Facing tool holder (L/H) 25×25 mm 1 set

- Boring bar holder ø32 mm 4 sets

- Boring bar socket ø32 mm 1 set with 8/10/12/16/20/25 mm

- U-Drill holder ø32 mm

- U-Drill sockets ø32 mm 1 set with 16/20/25 mm

- Drilling sockets ø32 mm MT 1/2/3

- Operator and Maintenance/Parts manuals