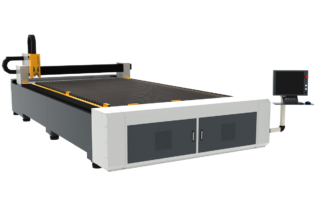

Open Type Fiber Laser

Product Highlights

With its compact size and cost-effective operation, this machine series stands out as the ideal choice for businesses operating within tight budgets, offering economic and practical solutions. Occupying just 15 square meters, it’s easily installed and comes in 1kW, 2kW, and 3kW power variants.

Primarily utilized in advertising, billboard production, electrical cabinet manufacturing, water tank fabrication, steel door production, metal furniture manufacturing, as well as coffee table and kitchenware production industries, this fiber laser cutting machine delivers efficiency without occupying excessive space, thanks to its single-table design, making it convenient for transportation.

Precise, Fast, and Reliable

Ideal for rapid and repetitive tasks, it features standard nesting software for swift part preparation and includes a flycut-cutting feature. Various cutting area options including 1.5×3 m, 2×4 m, or 2×6 m cater to diverse production needs.

Equipped with an auto-focus laser head and Active Anti-collision Function with auto-view capability, it ensures precision and safety during operation. Additionally, the cutting heads feature automatic cooling for consistent performance.

Constructed with one-piece aluminium alloy sheet-plate welded bridges, these machines guarantee rigidity and prevent deformation under impact, overlap, or strain. Their lightweight structure, three times lighter than steel profile bridges, enables high speeds and accelerations at lower engine power, enhancing operational efficiency. All machines adhere to European standards and are CE-certified.

| Specifications | FLO-1530 | FLO-2040 |

|---|---|---|

| Working Area | 1500 x 3000 mm (5 x 10 ft) | 2000 x 4000 mm ( 6.5 X 13 ft) |

| Loading Capacity | 1200 kg (2650 lbs) | 1200 kg (2650 lbs) |

| X-Y Axis Travel | 1520 x 3030 mm (5 x 10 ft ) | 2020 x 4050 mm (6.6 x 13.3 ft) |

| Z Axis Travel | 100 mm (3.94”) | 100 mm (3.94”) |

| X-Y-Z Axis Guideway | 4 Point Ball Caged | 4 Point Ball Caged |

| X-Y Axis Drive System | Rack | Rack |

| Z Axis Drive System | Ballscrew | Ballscrew |

| X-Y Axis Speed | 80 m/min (3150 ipm) | 80 m/min (3150 ipm) |

| Z Axis Speed | 30 m/min (1180 ipm) | 30 m/min (1180 ipm) |

| X-Y Position Accuaracy | 0.05 mm (0.002”) | 0.05 mm (0.002”) |

| X-Y Repeatability Accuracy | 0.03 mm (0.001”) | 0.03 mm (0.001”) |

| Laser Source | Raycus / JPT / Han’s | Raycus / JPT / Han’s |

| Laser Source Output Power | 1000 / 2000 / 3000 W | 1000 / 2000 / 3000 W |

| CNC Control System | Fscut | Fscut |

| Laser Cutting Head | Raytools / BOCI / WSX | Raytools / BOCI / WSX |

| Assist Gasses | Air / Oxygen / Nitrogen | Air / Oxygen / Nitrogen |

| Cooling Type | Water Cooling | Water Cooling |

| Machine Weight | 4500 kg (9900 lbs) | 4000 kg (8818 lbs) |

| Machine Dimensions (W x L x H) | 2355 x 8580 x 1980 mm (7.7 x 28.1 x 6.5 ft) | 3000 x 5700 x 1980 mm (9.8 x 18.7 x 6.5 ft) |

| Graphic Format | dwg / dxf / stp | dwg / dxf / stp |

| Electricity | 220 or 380 Volt / 3 phase / 60 Hz | 220 or 380 Volt / 3 phase / 60 Hz |

| Certifications | CE / ISO | CE / ISO |

| Cutting Thickness | 1000w | 2000w | 3000w |

|---|---|---|---|

| Cutting Thickness | 1000 w | 2000 w | 3000 w |

| Carbon Steel | 10 mm (3/8”) | 14 mm (9/16”) | 16 mm (5/8”) |

| Stainless Steel | 3 mm (1/8”) | 5 mm (3/16”) | 6 mm (1/4”) |

| Aluminium | 2 mm (1/16”) | 4 mm (1/8”) | 5 mm (3/16”) |

| Brass | 2 mm (1/16”) | 4 mm (1/8”) | 5 mm (3/16”) |