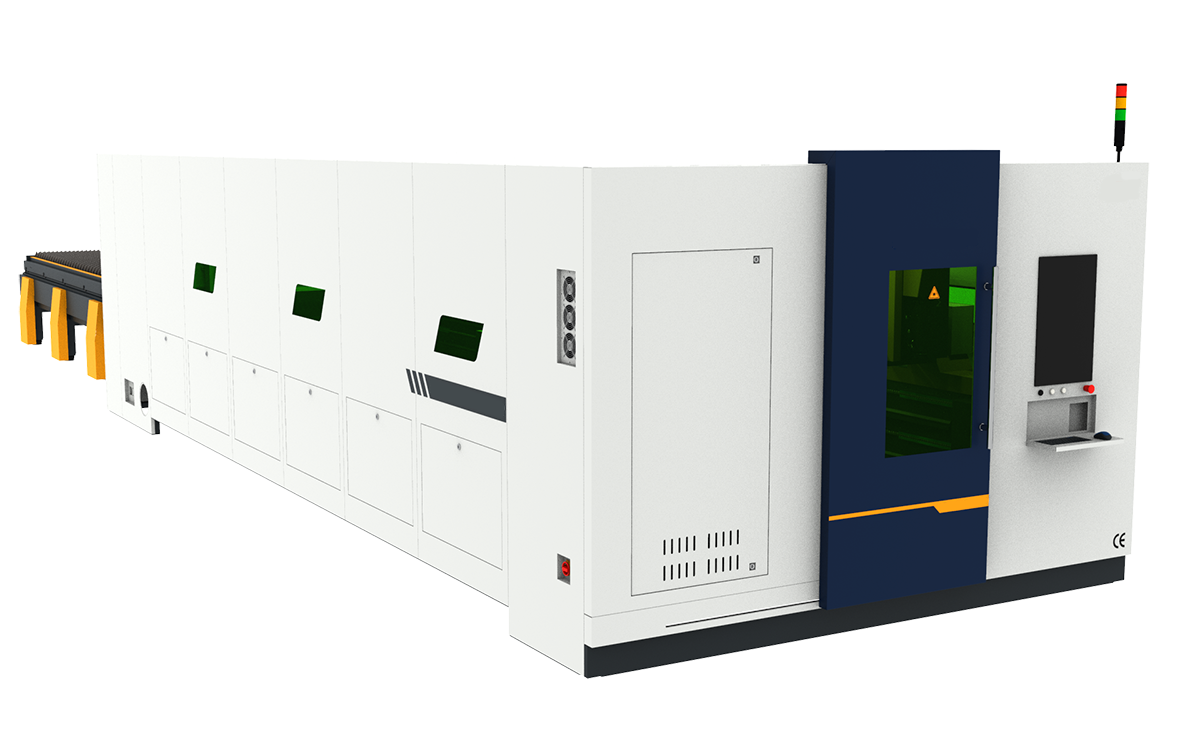

Close Type Fiber Laser

Product Highlights

The FLC series epitomizes speed, sensitivity, reliability, and cost-effectiveness in fiber laser cutting machines. This high-efficiency equipment adheres to top-tier standards in the industry. Capable of handling laser power of up to 30,000 W, it’s an excellent choice for cutting thick plates efficiently. Industries such as agriculture, textile, food machinery, construction, lifting equipment, and other large-scale machinery manufacturing sectors prefer the FLC fiber laser cutting machine for its precision and effectiveness.

Ideal for those considering outsourcing, the FLC series offers convenient features like blowing, cutting, pause, calibration simulation, etc., accessible through its wireless remote control. Equipped with standard nesting software, it swiftly prepares parts for cutting, eliminating the need for constant operator supervision. Its flycut-cutting feature further enhances efficiency.

With a double exchange table design, continuous cutting is possible without delays. All machines are manufactured in compliance with European standards and hold CE certification. The FLC machines boast a nozzle cleaning system and a double camera setup for enhanced performance.

Customers can choose from cutting area options of 1.5×3 m, 2×4 m, or 2×6 m to suit their needs. The laser head features auto-focus, Active Anti-collision Function, and an auto-view feature that detects obstacles and adjusts automatically. Automatic cooling ensures optimal performance of cutting heads.

Our machines feature bridges constructed from aluminum alloy sheet-plate welding, ensuring a single-piece, rigid structure. This design prevents deformation due to impact, overlap, or strain, maintaining stability during operation. Compared to steel profile bridges, the lightweight aluminum construction enables higher speeds and accelerations with lower power requirements.

| Specifications | FLC-1530 | FLC-2040 | FLC-2060 |

|---|---|---|---|

| Working Area | 1500 x 3000 mm | 2000 x 4000 mm | 2000 x 6000 mm |

| Loading Capacity | 1200 kg | 1200 kg | 1450 kg |

| X-Y Axis Travel | 1520 x 3030 mm | 2020 x 4040 mm | 2020 x 6050 mm |

| Z Axis Travel | 300 mm | 300 mm | 350 mm |

| X-Y-Z Axis Guideway | 4 Point Ball Caged | 4 Point Ball Caged | 4 Point Ball Caged |

| X-Y Axis Drive System | Rack | Rack | Rack |

| Z Axis Drive System | Ballscrew | Ballscrew | Ballscrew |

| X-Y Axis Speed | 100 m/min | 80 m/min | 100 m/min |

| Z Axis Speed | 30 m/min | 30 m/min | 30 m/min |

| X-Y Position Accuracy | 0,05 mm | 0,05 mm | 0,05 mm |

| X-Y Repeatability Accuracy | 0,03 mm | 0,03 mm | 0,03 mm |

| Table Change Time | 10 sec | 10 sec | 10 sec |

| Laser Source | Raycus / Han’s / JPT | Raycus / Han’s / JPT | Raycus / JPT / Hans |

| Laser Source Output Power | 2 / 3 / 4 / 6 / 8 / 12 / 20 kW | 2.000 ⟺ 20.000 W | 2 / 3 / 4 / 6 / 8 / 12 / 20 kW |

| CNC Control System | Fscut | Fscut | Fscut |

| Laser Cutting Head | Raytools / BOCI / WSX | Raytools / BOCI / WSX | Raytools / BOCI / WSX |

| Assist Gasses | Air/Oxygen/Nitrogen | Air/Oxygen/Nitrogen | Air/Oxygen/Nitrogen |

| Cooling Type | Water Cooling | Water Cooling | Water Cooling |

| Machine Weight | 8500 kg | 10000 kg | 11500 kg |

| Machine Dimensions (WxLxH) | 2698 x 9175 x 2560 mm | 3500 x 11200 x 2560 mm | 4400 x 10000 x 2120 mm |

| Graphic Format | dwg / dxf / stp | dwg / dxf / stp | dwg / dxf / stp |

| Voltage | 380 / 50 Hz | 380 / 50 Hz | 380 / 50 Hz |

| Certifications | CE / ISO | CE / ISO | CE / ISO |