Full Line of CNC Horizontal Turning Centers

Not sure which horizontal turning center CNC is for you?

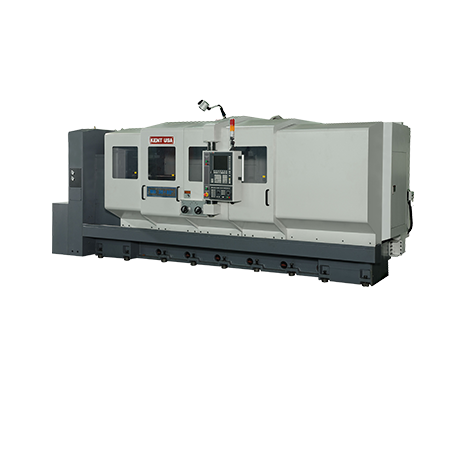

The Kent CNC Horizontal Turning Centers

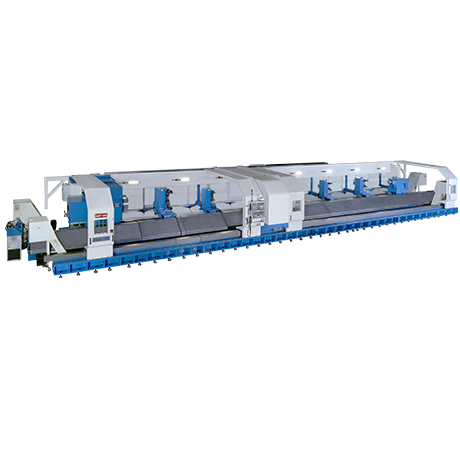

Our broad range of horizontal turning centers offers a variety of bore sizes, bed lengths, and optional features. From basic 2-axis turning to sub-spindle and live turret turning models, there is a Kent CNC turning center to meet your needs. For even larger and more complex jobs, check out our Large Bore, Heavy Duty, 5 Bed Way Extra Long, 5-Axis Milling Turning, and Double Turret Series.

Turning Center Functions

A CNC lathe can perform many tasks but a turning center is capable of much more such as:

1. Facing. Removing the metal from the end of a workpiece (typically cylindrical) which produces a flat surface.

2. Threading. This is the process of making a screw thread used to fasten or connect items.

3. Knurling. A process of machining a pattern of angled or crossed lines rolled into the workpiece. A finished knurled piece allows hands to get a better grip on the object.

4. Drilling. Most often, drilling holes in a workpiece will need to be done on the lathe before other tasks can be completed, such as tapping, boring or reaming. It’s always best to spot or center-punch the area to be drilled so that the drilling will be correctly aligned.

5. Boring. This enlarges the hole in the workpiece that was already drilled, achieving greater accuracy of the diameter of the hole.

6. Reaming. Drilled holes in the workpiece are often not accurate (straight and cylindrical). Reaming finishes and sizes the drilled holes with a high degree of accuracy.

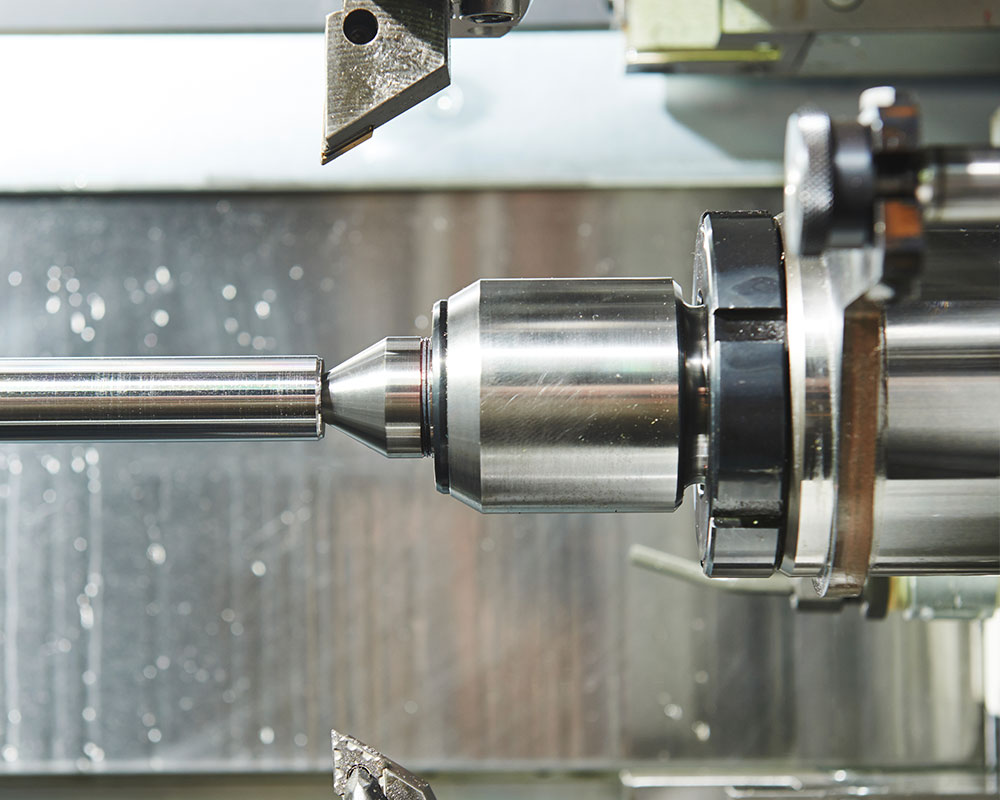

7. Taper Turning. A taper is a uniform change in the shape of a cylinder’s diameter when measured along its axis. It is created by angling the workpiece and cutting tool relative to each other as the tool travels along the workpiece surface, cutting deeper or shallower, thus creating a tapered surface.

CNC Turning Uses and Applications

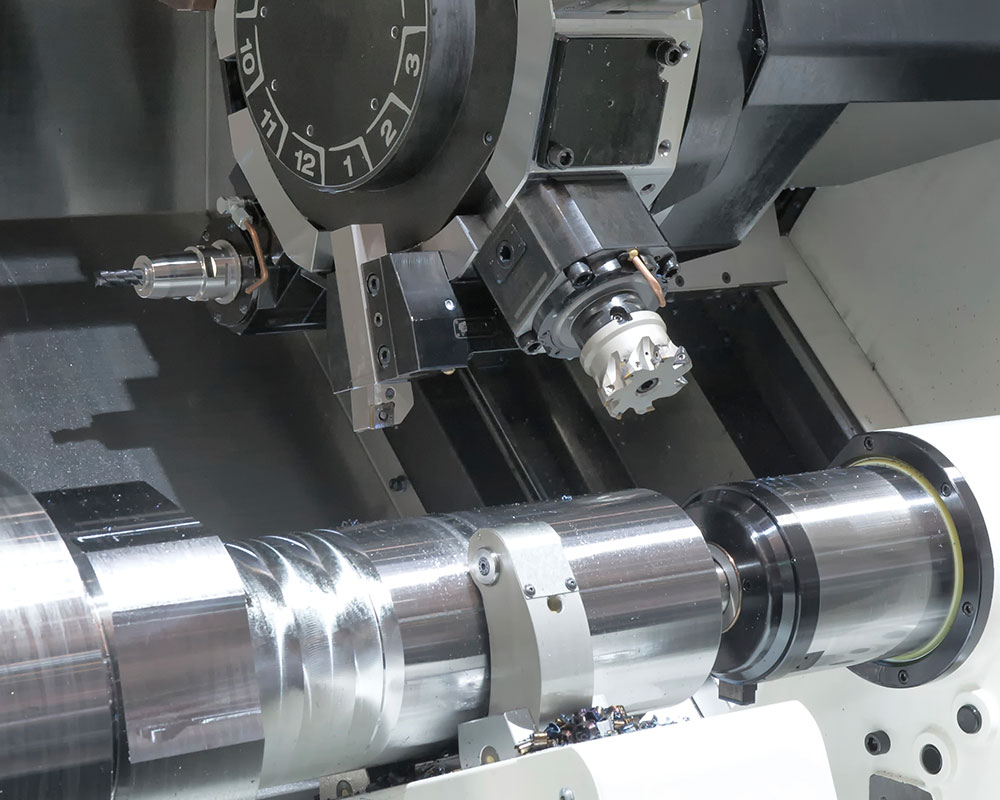

Aerospace, automotive, medical, oil and gas, etc. are some of the industries where CNC turning centers are utilized. These machines do particularly well with machining round metal parts, bars, tubes, gears, etc. Multitasking is the word that best describes live tools powered turrets. Live tooling allows the lathe to mill, drill, bore, turn, and tap workpieces. The benefit is reduced work-process time, which increases your productivity and profitability. Kent CNC offers a full range of CNC Turning Centers with live tooling, dual spindles, Y-axis, multiple turrets, and robot tending to meet simple to complex machining applications and solutions.

Live Tooling

Multitasking is the word that best describes live tooling. Live tooling allows a CNC turning lathe to mill, drill, bore, turn and tap workpieces. The benefit is it reduces work-process time which increases your productivity and profitability. Kent CNC offers CNC Turning Centers with Live Tooling that will fit the more complex applications.

Reliable Round the Clock

Kent CNC’s machine designs enable manufacturers to hold tight tolerances and eliminate the need for separate finishing or grinding operations. Kent CNC’s integration with Fanuc controls create production efficiency and ease of use. With having a distributor in nearly every state, you can find a local Kent CNC premium distributor who can assist you should you require any technical or service assistance. To find your local Kent CNC dealer, contact our California sales office at +1-714-258-8526.

Not sure which horizontal turning center CNC is for you?

Our Happy Customers