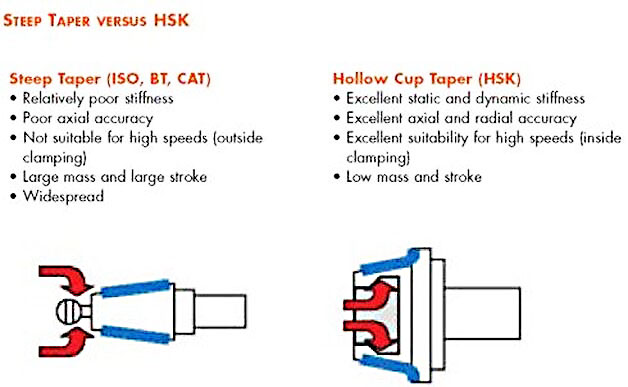

Thinking about changing out your CNC toolholders? Big decision. Most machining centers today come standard with a CAT or BT-style spindle interface, and for the lion’s share of milling operations, these do the job quite nicely. But sometimes, an alternative to traditional “steep taper” CNC toolholders is in order.

Source: nextgentooling.com

Choose the Right CNC Toolholders

Of course, moving to different CNC toolholders means buying a new machine. Exciting times. Maybe your shop wants to move into high-speed machining and want to achieve better toolholder balance. Maybe you’re milling lots of Inconel and other tough materials and want to improve tool life. Or maybe you want to remove more material in less time and know that dual-contact CNC toolholders offer greater rigidity. Whatever the reason, the first thing to do is learn all you can about the available options.

Source: bigdaishowa.com

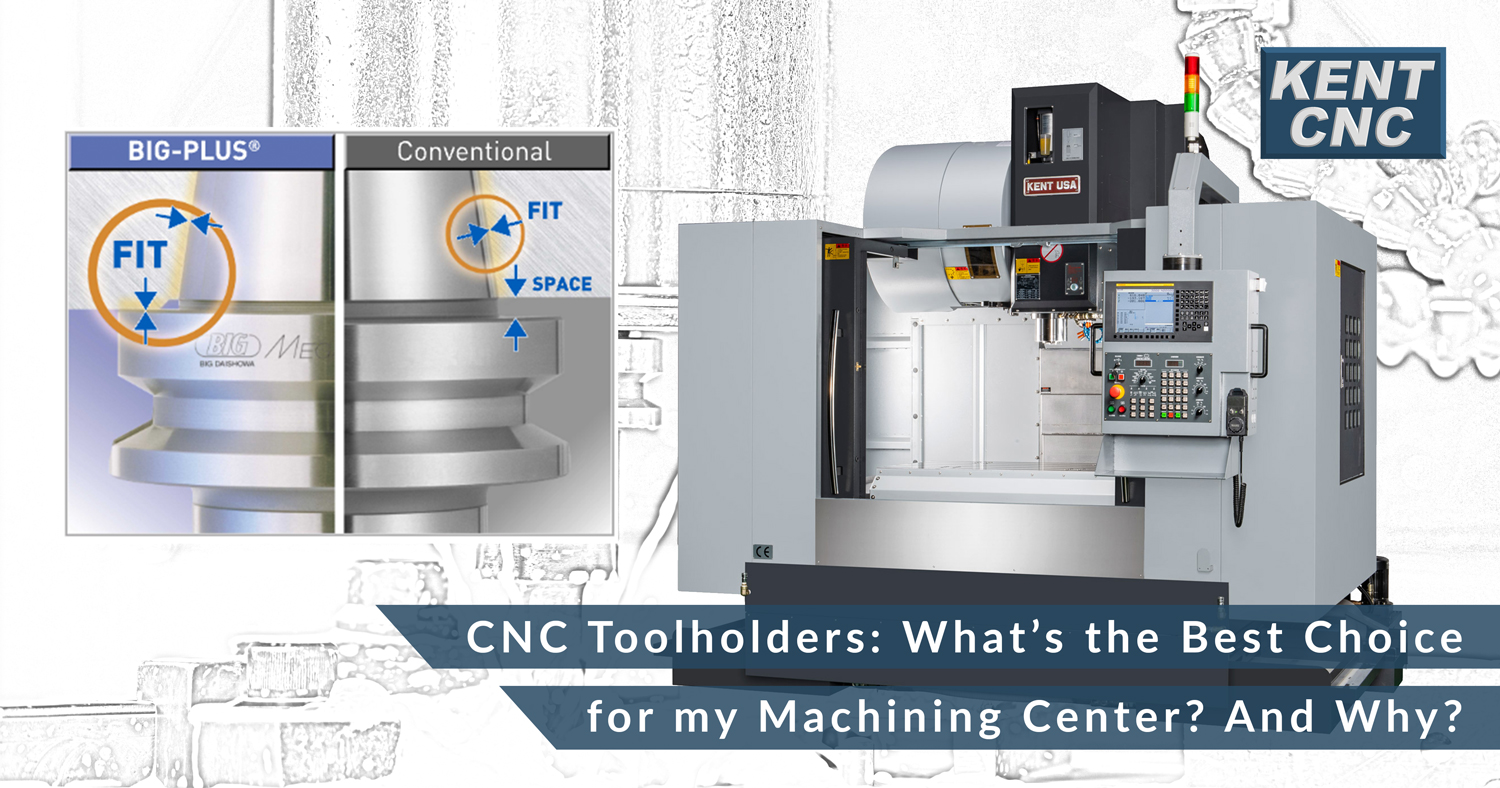

Dual Contact CNC Toolholders

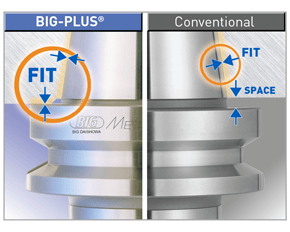

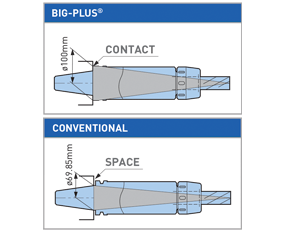

For starters, what does dual-contact mean? And why is it (supposedly) such a big deal? Great question. Instead of engaging along the spindle taper only, dual-contact CNC toolholders seat on the spindle face as well. This increases rigidity while reducing runout, both of which help to improve productivity and tool life.

Source: bigdaishowa.com

The Down Side

Of course, everything has a cost. BIG-PLUS and HSK are more expensive than steep taper holders. They’re also more susceptible to grit and chips, which can get caught between the spindle face and mating surface, so plan on paying special attention to cleanliness (which you should be doing anyway). Furthermore, the higher spindle speeds might be just the ticket for maximizing metal removal, but be prepared to spend even more money. Aside from the cost of the toolholders, you’ll probably need a tool balancing machine for those higher spindle speeds. While you’re at it, though, you might as well get an offline tool presetter.

It’s About Being Progressive

The good news is, both of these machining technologies will reduce downtime due to premature tool wear. They’ll also shorten setup times. No more using your CNC machining center to touch off tools. No more fat fingering an offset and watching it pile into the workpiece. That said, you can use offline presetting and toolholder balancing without investing in different toolholders. By all means, go for it. But for those willing to make the leap to modern CNC toolholders like HSK and BIG-PLUS, most will soon find themselves changing tools less often and seeing more parts on the table at the end of the day.