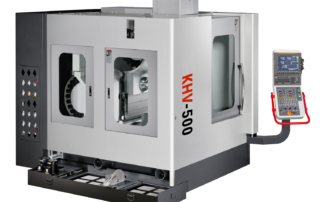

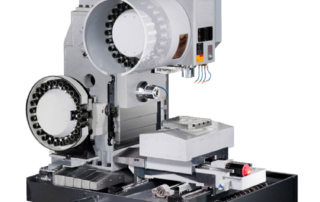

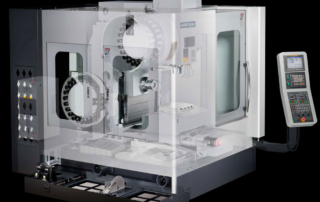

Combination Spindle KHV Series

Product Highlights

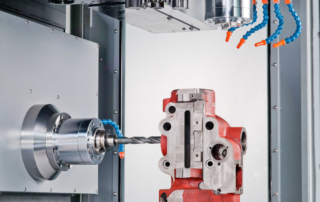

Kent CNC has introduced the New Kent CNC KHV-400 Combination Horizontal/Vertical Machining Center with the industry standard 0i-MD control by FANUC. Kent CNC sets a new industry standard with their latest combination dual spindle machining center, model KHV-400. By combining a horizontal machining center with a vertical machining center, this cutting-edge versatile machining center allows for faster setups and parts loading and unloading, improved accuracy, floor space maximization, and capital investment reduction.

Two Spindles are Better than One

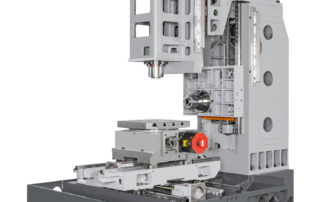

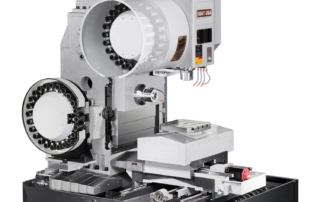

It includes a powerful 10 HP (Horizontal)/15 HP (Vertical), 10,000 RPM (Opt. 12,000) spindle with Direct Drive Spindle Motor as standard. Both the horizontal and vertical travels are 19.7” X-axis by 19.7” Y-axis by 17.8” Z-axis with fast two-set 24-tool ATC. In addition, the rapid traverse for each axis is 36m/min that is upgradeable to up to 48m/min. The rotary table is equipped with an optical scale.

This Meehanite certified machine allows for five-sided machining in one setup for fast production and accuracy all in a compact floor space of 82” x 114”.

| KHV-400 | KHV-500 | KHV-1100 | |

|---|---|---|---|

| X Axis travel | 19.7″ | 43.3″ | 43.3″ |

| Y Axis travel – Vertical | 19.7″ | 23.6″ | 26.4″ |

| Z Axis travel – Vertical | 17.7″ | 26.4″ | |

| Y Axis travel – Horizontal | 19.7″ | 26.4″ | |

| Z Axis travel – Horizontal | 17.8″ | 23.6″ | 26.4″ |

| Vertical Spindle center to column | 25.78″ | 31.9″ | |

| Vertical Spindle nose to table top | 4.9″ – 22.6″ | 4.5″ – 22.2″ | 3.3″ – 29.3″ |

| Horizontal Spindle nose to table center | 4.9″ – 24.6″ | 4.9″ – 28.5″ | 7.5″ – 31.3” |

| Horizontal Spindle center to table top | 2.95″ – 20.67″ | 3.5″ x 21.3″ | 4.7″ – 29.1″ |

| Table height from the floor | 43″ | 42.9″ | 53.15″ |

| Table load capacity | 772 lbs | 882 lbs | 1323 lbs |

| Spindle nose (BT / CAT / DIN) | BT40 / CAT40 / ISO40 | ||

| Spindle RPM (Vertical) | 10,000 RPM (Opt. 12,000) | ||

| Spindle RPM (Horizontal) | 10,000 RPM (Opt. 12,000) | ||

| Main motor (cont./ 30min) | 10 HP / 15 HP (Direct Drive) | 15 HP / 20 HP (Direct Drive) | |

| A.T.C. Magazine for arm type (H/V) | 24/24 (Opt. 24/40) | 24/24 (Opt. 40/40) | |

| A.T.C. tool diameter | 2.99″/5″ | ||

| A.T.C. tool length | 9.8″ | 11.8″ | |

| A.T.C. tool weight | 15.4 lbs | ||

| Rapid traverse | 32 m / Opt. 48 m | 24 m | |

| Cutting feed | 1 – 15000 mm | ||

| Repeatability | ±0.0000787″ | ||

| Rotary table – Table top dimension | 19.68″ x 19.68″ | 24.8″ x 24.8″ | |

| Rotary table – T-slots( wide× no.× pitch) | 14H7 x 5 x 80 mm | 18H7 x 5 x 100 mm | |

| Rotary table – Speed reduction ratio | 1:90 | 1:120 | |

| Rotary table – Min. indexing (degree) | 0.001° | ||

| Rotary table – Max. rotation speed | 33.33 rpm | 25 rpm | |

| Rotary table – Positioning accuracy | 10 seconds | ||

| Rotary table – Repeatability | *** | *** | |

| Rotary table – Max. load | 772 lbs | 882 lbs | 1323 lbs |

| Coolant system | 580 W | ||

| Lubrication system | 25 W | ||

| Air pressure | 85 PSI | ||

| Machine weight | 18739 lbs | 19950 lbs | 32407 lbs |

| Floor space ( L x W x H ) | 114″ x 106″ x 115″ | 120″ x 106″ x 115″ | 177″ x 138″ x 140″ |

| CNC Controller | Fanuc 0i-MF / 32i-MB | ||