In a recent article about CNC Toolholders, we compared traditional “steep taper” milling machine toolholders to their dual-contact HSK and Big Plus alternatives. This time, we’ll explore the CNC turning equivalent, a.k.a. quick-change toolholders. As their name suggests, these aftermarket devices make swapping out a broken drill or worn turning tool fast and easy. The result is greater uptime, more parts out the door, and less chance of a costly mistake.

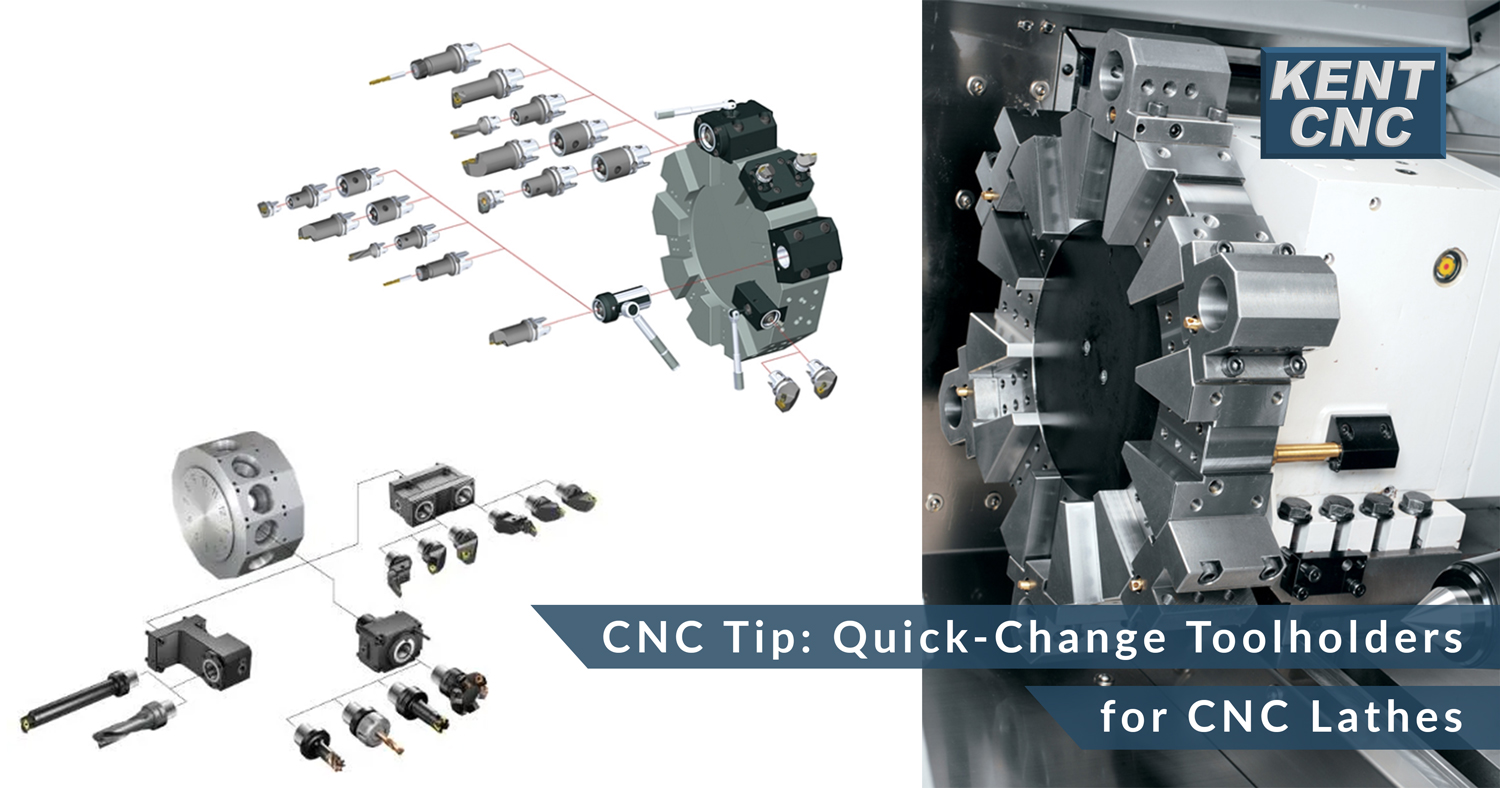

How Do They Work?

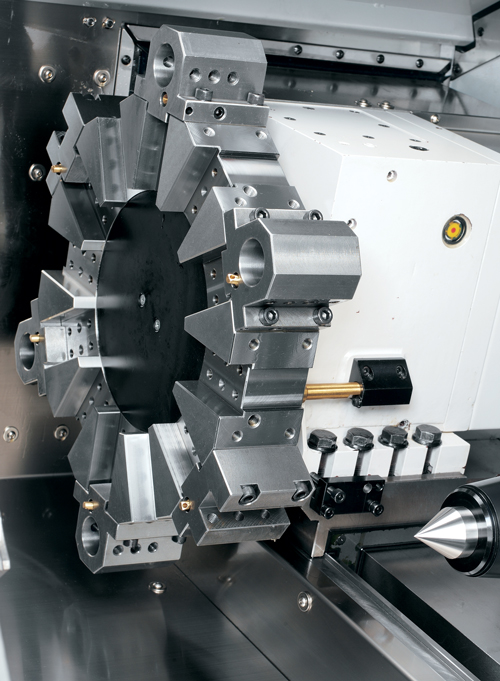

Quick-change toolholders have a cam or screw mechanism that locks a proprietary removable head in place, allowing the base to remain in the machine. The heads can carry different cutting tools—a drill, for example, or an 80-degree diamond. There’s no more leaning into the machine. No dropped screws or inserts. No more using your CNC lathe as an expensive toolsetter. Simply remove the head with its worn tool, load up a replacement, and push cycle start. That’s it.

Do I Need Quick-Change Toolholders for Milling Work?

But hold on. Why aren’t we talking about CNC machining center tooling? Yes, quick-change collet chucks and end mill holders might save time during tool replacement. Yet tool changes are already fast for those who set up the machining center. Just load the toolholder into the spindle or tool carousel and clamp it in place. If you’ve invested in an offline presetter, you’re ready to go. Otherwise, touch the tool off on the workpiece or tool-setting probe and get to work.

Are Quick-Change Toolholders Worth the Cost?

Maybe your CNC lathe is set up to make gazillions of brass or plastic parts. In this instance, tool changes are rare, so who cares if it takes another minute or two? In most other situations, the answer is a resounding yes. For example, set-up times are much shorter. So are cutting tool replacements. In either case, there’s no need to touch off, no fumbling in the machine with Allen wrenches. As noted earlier, it’s fast and easy, which is why most experts say quick-change toolholder payback times are best measured in months, maybe weeks.

Which Quick-Change Toolholders Are Best?

Granted, we’re not here to promote cutting tools or toolholders. We sell and service CNC lathes, machining centers, and other high-quality machine tools. That said, we’ve heard that Kennametal’s KM quick-change system is quite good.

So is Sandvik Coromant’s Capto.

Both are mature, popular options. But look around. Whatever one you end up with, they’re all quite easy to install on any of our turning centers, including the new KLT-series lathe. Best of all, you can start slow. Pick up one or two quick-change bases for your most frequently changed tools and go from there. It’s time to get more productive, and that’s what we’re all about.