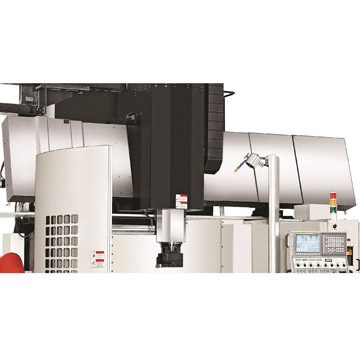

KVT Large Vertical Turning Center Series

Product Highlights

Kent USA offers a full range of CNC Vertical Turning Lathes, which combine proven machine design with advanced technology in control and manufacturing. The rigid machine structure enables higher machining efficiency with better finish and longer tool life, resulting in greater productivity and profitability.

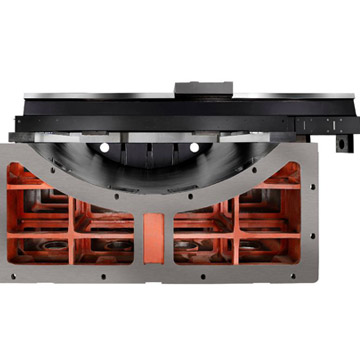

Unique Hydraulic Static Bearing Design – The floating hydraulic bearing is designed with a heavy-duty roller bearing. This sits in a rigid one-piece base casting, providing the ideal combination of increased table load and precision machining.

Patented Octagon RAM Design – The unique structure of all Kent USA models provides excellent straightness with improved control of thermal expansion. This special Octagon RAM provides superior damping characteristics and improved rigidity when compared with the traditional square RAM design.

Massive Hydraulic Clamps Lock Crossrail – Each position is locked by 4 strong independent hydraulic cylinders in conjunction with large taper lock pins. This design provides both flexible and rigid crossrails that provide the machine’s versatile capacity, superior positioning and repeatability control.

Saddle Structure – The 15˚ slant bed design is used on both KVT-160 and KVT-200 models. This reduces overhang problems and provides increased machine rigidity.

Multi-Ribbed Column – The one-piece column made from Meehanite cast iron and a wide span ribbed box structure provides strong stability and rigidity. It dramatically decreases vibration, thermal expansion and deformation caused by cutting stress. The oversized box slideways are heat-treated to Rockwell 55˚ and stress relieved.

Work Table – High rigidity work table with 4 jaw manual chuck.

Gear Box – The high torque, 2-speed gearbox matches to a Fanuc spindle motor with a maximum torque of 17,163 ft-lbs, providing a cutting power to suit all types of material.

| KVT-120/M | KVT-160/M | KVT-200/M | |

|---|---|---|---|

| Table Diameter | 49.2″ | 63″ | 78.7″ |

| Max Swing | 63″ | 78.7″ | 98.4″ |

| Max Turning Diameter | 63″ | 74.8″ | 98.4″ |

| Ram to Table Distance | 27.6″ – 59.1″ | 41.9″ – 73.4″ | |

| Max Turning Height | 47.2″ | 63″ | 71″ |

| Max Workpiece Weight | 17637 lbs | 22000 lbs | 33069 lbs |

| Ram Size | 9.1″ x 9.5″ | 9.5″ x 10.6″ | |

| Min ID for Ram Pass | 11.2″ | 12.2″ | |

| Table Speed (2 Steps) | 0.0394″ – 4.72″, 0.0394″ – 11.8″ | 0.0394″ – 2.76″, 0.0394″ – 9.8″ | 1 – 200 RPM |

| Max Torque of Table | 7860 ft lb | 13860 ft lb | 41155 ft lb |

| Live Spindle Speed | – / M: 24 – 2400 RPM | – / M: 50 – 2250 RPM | – / M: 50 – 2250 RPM |

| X-Axis Travel | -7.87″ to 37.4″ | -7.87″ to 44.3″ | -51″ to 59.4″ |

| Z-Axis Travel | 35.4″ | 39.4″ | 49.2″ |

| Crossrail Travel | 31.5″ | ||

| Crossrail Step | 7.87″ x 5 | ||

| X-Axis Rapid Traverse | 472.4 ipm | 393.7 ipm | |

| Z-Axis Rapid Traverse | 393.7 ipm | ||

| ATC Capacity | 12 / M: 18 | ||

| Max Tool Length | 15.7″ | ||

| Max Weight of Tool Holder | 110 lbs | ||

| Max Weight of Magazine | 992 lbs / M: 1213 lbs | ||

| Type of Tool Shank | BT50 | ||

| Tool Shank Size | 0.98″ / 1.26″ | ||

| Spindle Motor | 50 HP / 60 HP | ||

| Total Power Capacity | 50 kvA | 60 kvA | |

| X/Z-Axis Servo Motor | 8 HP | ||

| Live Spindle Motor | M: 9.4 HP | ||

| CF-Axis Servo Motor | M: 10 HP / 15 HP | ||

| Floor Space | 232″ x 150″ | 256″ x 181″ | 307″ x 201″ |

| Machine Height | 198″ / M: 211″ | 224″ / M: 232″ | 226″ / M: 234″ |

| Machine Weight | 44092 lbs / M: 45195 lbs | 61730 lbs / M: 62830 lbs | 92594 lbs / M: 93700 lbs |

Standard Accessories

- Independent 4 Jaw Manual Chuck

- 12 Tools of ATC for KVT series

- 18 Tools of ATC for KVT(M) series

- Machine Cover (Semi-Opened)

- Oil / Water Separator

- Auto Lubrication System

- Tool Holder BT-50 (O.D. + I.D.) x 1 pcs

- Chip Conveyor

- Heat Exchanger for Electrical Cabinet

- Work Light and Signal Tower Light

- High Pressure Pump (3 Bar)

- Tools and Tool Box

- Hydraulic Unit

- Table Lubricant Oil Cooling Unit

- Anchor Bolt and Pad

- FANUC 0i-T Controller

- Operation Manual

Optional Accessories

- Air Conditioner for Electrical Cabinet

- Transformer for Power Source

- Additional Tool Holders

- Coolant Through Spindle

- X / Z-axis Linear Scale

- Tool Probe

- Parts Probe

- 3 Jaw Power Chuck

- High Pressure Pump (6 Bar)

- High Pressure Pump (10 Bar)

- CF-axis

- CAT Tool Magazine