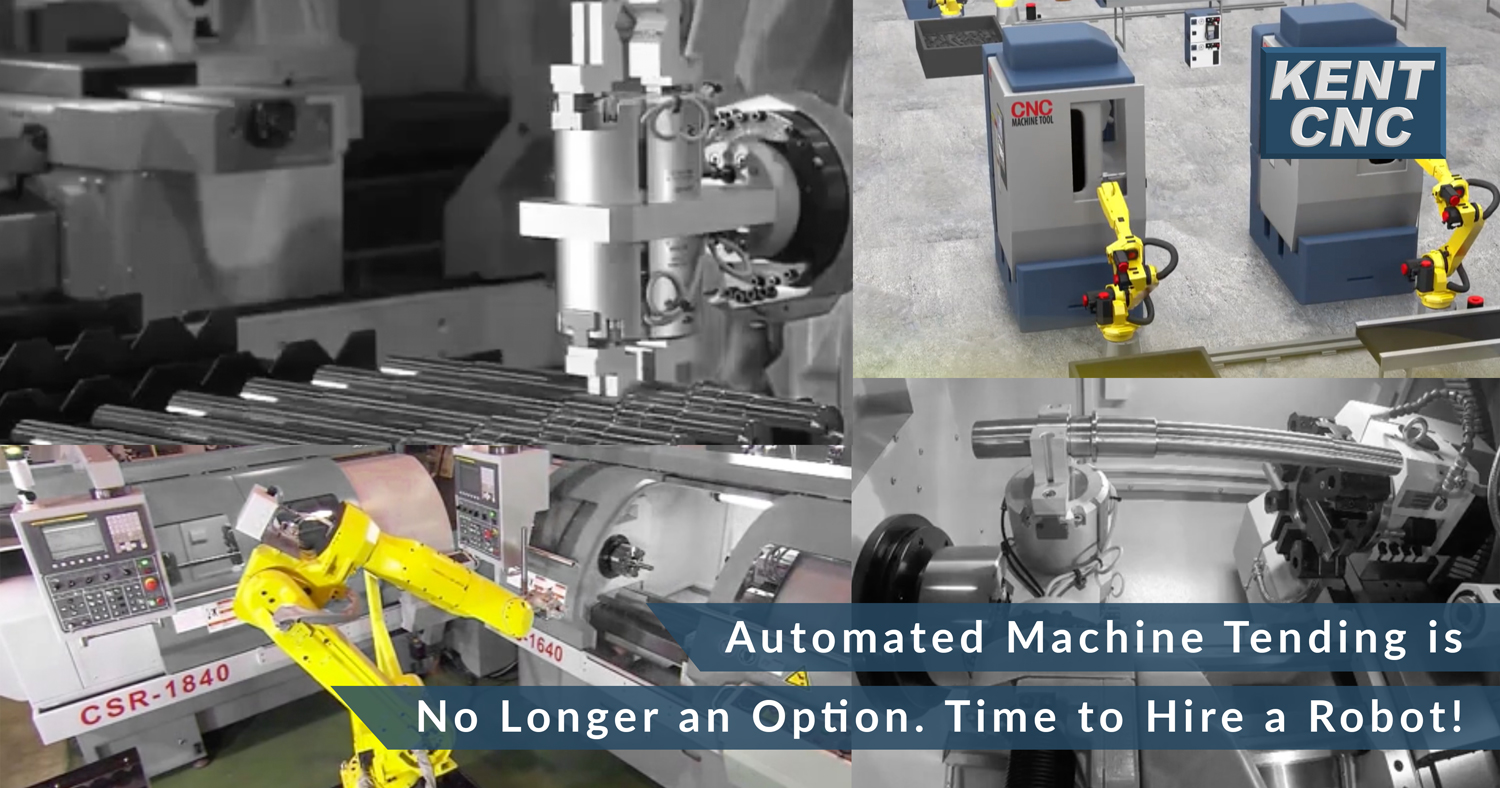

Automated Machine Tending is No Longer an Option. Time to Hire a Robot!

Given the ongoing shortage of skilled labor, shops everywhere are turning to automated machine tending. Doing so reduces operating costs. It increases overall equipment effectiveness (OEE), often significantly. Automation also opens the door to unattended second and third shifts, potentially allowing the company to earn new business. That’s because robots don’t call in sick. They don’t take breaks, go on vacation, or stand around talking about last night’s big game. They just work, and work hard. And contrary to what some might say, robots don’t put people on the unemployment line—just the opposite. Automated shops crank out more work. They make more revenue and increase overall efficiency. The bottom line? More money and security for all involved.

Automated Machine Tending Basics

Okay, great. So what’s involved? For one thing, you’ll have to master a few terms. For example, there are the robots we’ve seen pictured on automotive assembly lines, and then there are cobots. Short for collaborative robots, cobots can work alongside humans. They are “force and speed limited,” so there’s less need for safety guarding. This often makes them an easier and slightly less expensive alternative to traditional industrial robots. It would help if you also learned all you can about that safety guarding. Robots are cool, but there are times when a fast, you’d-better-get-out-of-the-way robot is a better choice. Then there are machine interfaces, teach pendants, programming and simulation software, end effectors, and much more to contend with. Automated machine tending is awesome, but it takes time, effort, and money to implement.

An Automated Machine Tending Example

Consider a machine like Kent USA’s KLR 2-Axis CNC lathe, or one of the company’s KVR- series machining centers. Since both come with FANUC controls, that means they’re Ethernet capable. So aside from making them easy to network (something that every shop should do), they’re also easy to integrate with a robot or cobot. But even without an Ethernet connection, any automation integrator will have no problem connecting your new non-stop worker to any CNC machine tool (even if it’s not a Kent).

They can also help you with the fencing or guarding mentioned earlier. There will suggest the best ways to feed the robot with raw material, and what to do with the finished parts when done. They will tell you all about grippers and end-effectors. But don’t worry. These and other concerns are no big deal, even if they might seem like it at first. Lastly, don’t forget the training. You’ll still need people. But instead of loading and unloading parts all day, they’ll now be doing more interesting tasks, robot tending among them. They’ll be safer as well, and go home at night dreaming of little droids. Kent USA can assist with all of this and more. As a FANUC strategic partner, we can help you get started on your automation journey in the most painless manner possible, whether robot, cobot, or something else entirely. The skilled labor problem isn’t going away soon, if ever. It’s time to automate.