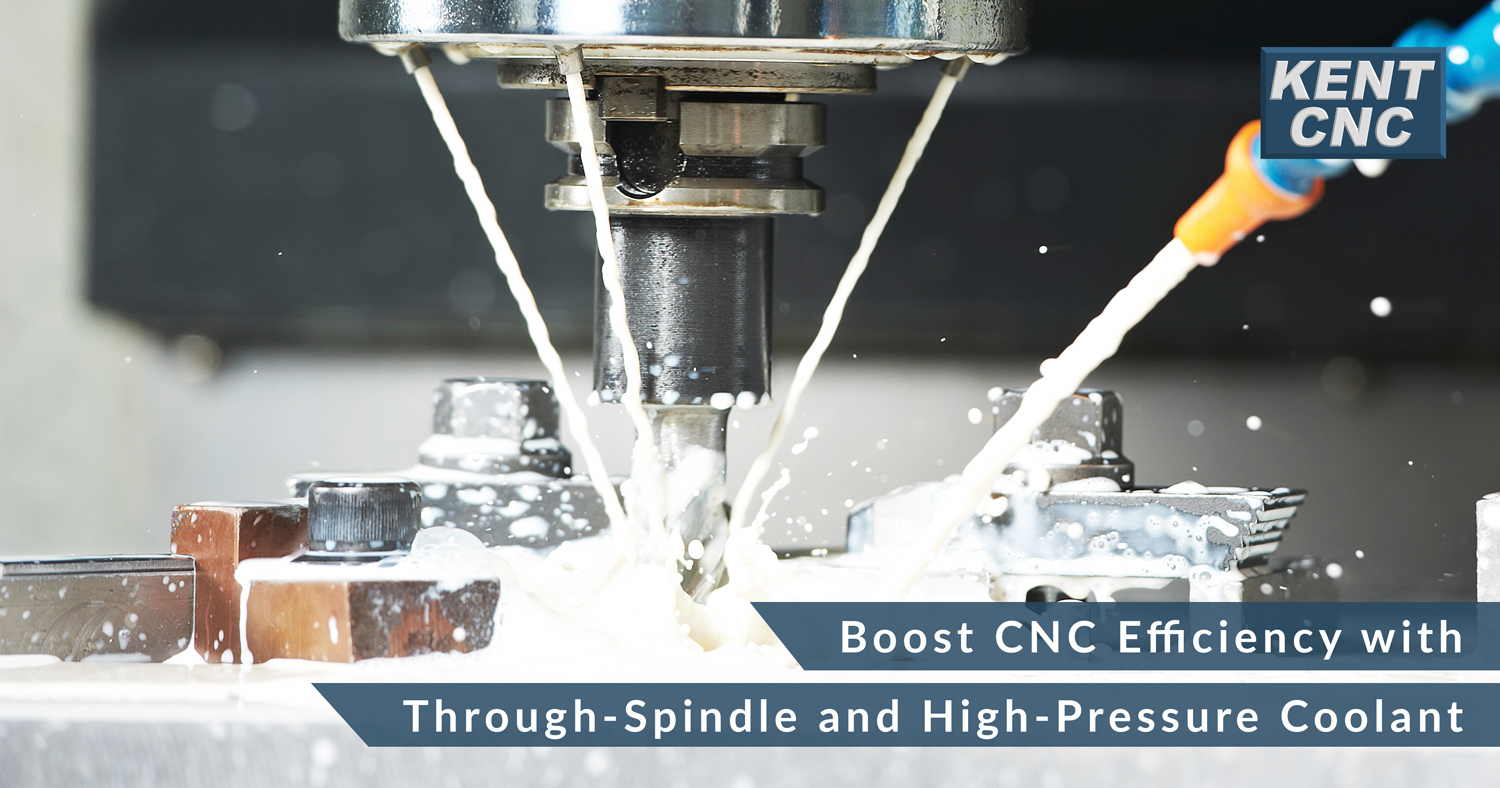

Anyone who’s watched an expensive carbide drill go up in smoke knows the importance of cutting fluids. And yet, the challenge is getting these fluids where they’re needed most: in the work zone. That’s where through-spindle coolant comes in. A common option on some brands of CNC machining center, “coolant-thru” increases tool life, productivity, and part quality alike.

What is Through-Spindle Coolant?

Some refer to through-spindle coolant as “coolant through the spindle” or simply CTS. Whatever you call it, CTS works just as its name implies. The machine builder installs a rotary union at the top of the spindle, some plumbing and hoses, and voila, your cutting tools are now cool and well-lubricated.

As with Kent USA’s KVR-series linear way and heavy-duty, high-speed box way VMCs, some CNC manufacturers prep their machining centers for through-spindle coolant. In addition, Kent offers 360° curtain coolant, which is a great way to flush chips away from the workpiece. No more recutting.

Of course, you’ll need cutting tools with internal passageways. The good news is, most indexable cutters come that way. So do many solid carbide drills and end mills. Yes, they might cost a bit more, but that’s a small price to pay for greater productivity.

Where Does High-Pressure Fit In?

Owners of CNC lathes don’t have to worry about coolant through the spindle. That’s because they have the turning equivalent, a.k.a. coolant through the turret. However, what they might not have is high-pressure coolant, or HPC. Just like through-spindle coolant on CNC machining centers, HPC is an excellent addition for anyone looking for better tool life and part quality.

But how high is high pressure? Opinions vary, but most experts draw the lines at 80 bar, or roughly 1000 psi. A word of warning, though; some HPC systems go much higher. Go too high and you can blow out a seal or damage the bearings. As always, be sure to check with your equipment distributor or machine builder if you have questions.