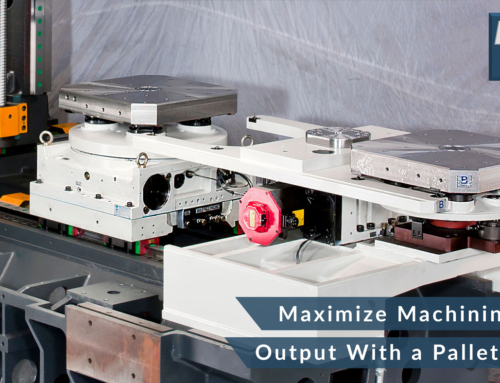

Combo Vertical and Horizontal Spindle Machining Center

Kent CNC has introduced the New Kent CNC KHV-400 Combination Horizontal/Vertical Machining Center with the industry standard 0i-MD control by FANUC.

Kent CNC sets a new industry standard with their latest combination machining center, model KHV-400. By combining a horizontal machining center with a vertical machining center, this cutting-edge versatile machining center allows for faster setups and parts loading and unloading, improved accuracy, floor space maximization, and capital investment reduction.

It includes a powerful 10 HP (Horizontal)/15 HP (Vertical), 10,000 RPM (Opt. 12,000) spindle with Direct Drive Spindle Motor as standard. Both the horizontal and vertical travels are 19.7” X-axis by 19.7” Y-axis by 17.8” Z-axis with fast two-set 24-tool ATC. In addition, the rapid traverse for each axis is 36m/min that is upgradeable to up to 48m/min. The rotary table is equipped with an optical scale.

This Meehanite certified machine allows for five-sided machining in one setup for fast production and accuracy all in a compact floor space of 82” x 114”. See other Horizontal Machining Centers here.