The two-axis slant bed lathe has long been an indispensable piece of the manufacturing equation. Machine shops use them to turn shafts, bore rings, cut threads, and perform countless other turning operations. But what if you could cut keyways in those shafts? How about drilling cross holes? Better yet, what if the lathe had a sub spindle? This would allow machinists to produce many parts complete in a single operation. Thanks to today’s advanced machine tool capabilities, all this and more is within reach.

Defining the Slant Bed Lathe

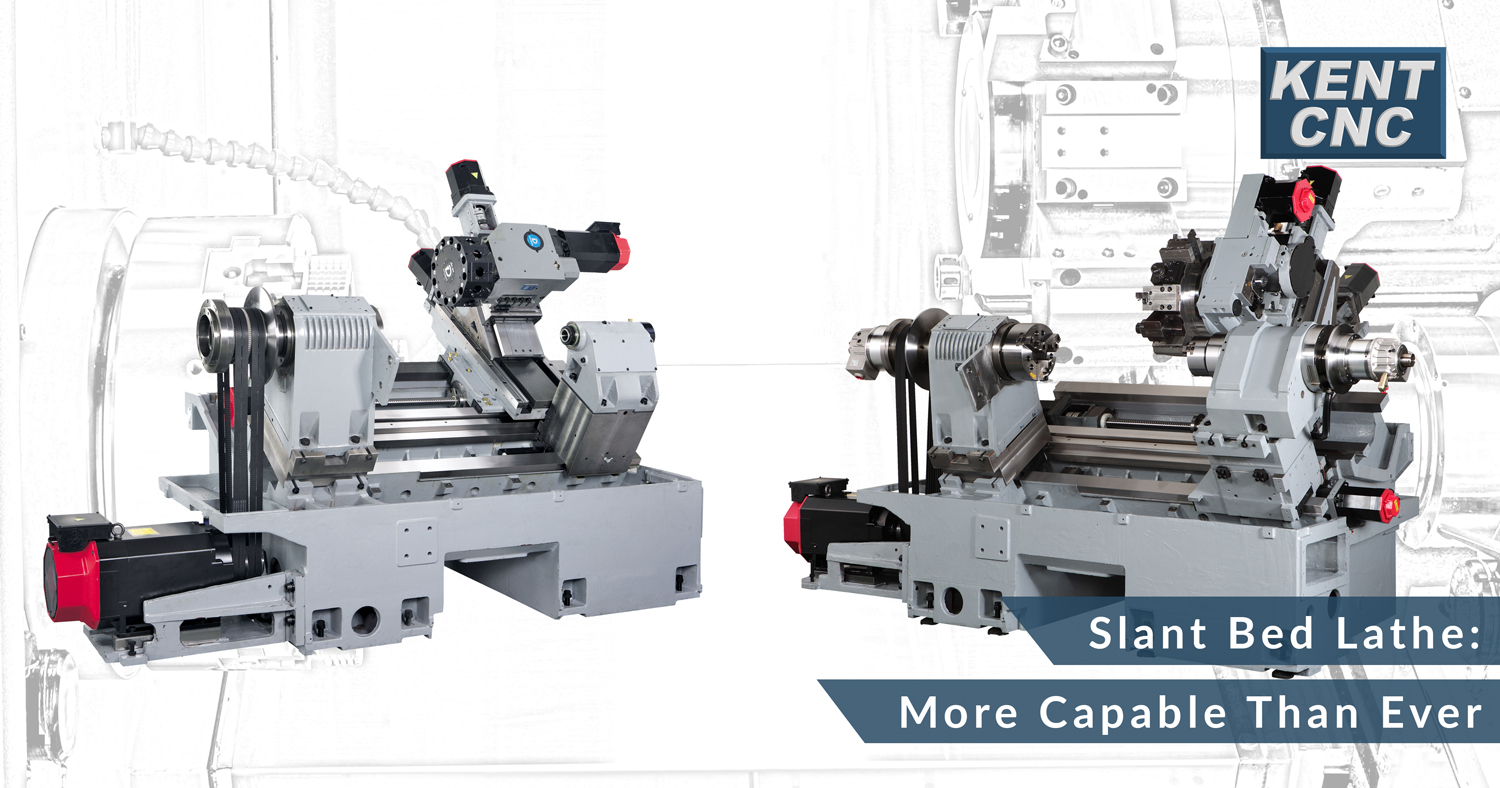

But what is a slant bed lathe, anyway? Simply put, it’s a CNC turning center whose bed is tipped at an angle. Because of this, chips fall more freely than on lathes with a “flat” or horizontal beds. What’s more, tipping the bed means larger X-axis travels are possible. This increases machine flexibility and capacity. For example, the KLR-200SM horizontal turning center from Kent USA has a 45° slant bed. An 8″ chuck machine, it has a 10.2″ diameter turning capacity and accommodates parts up to 19.5″ long. It also boasts a one-piece Meehanite casting for superior rigidity and vibration dampening. As you’ll see, however, there’s much more to the slant bed lathe story than enhanced chip flow or larger part size. There’s also increased productivity, reduced machining costs, and better part quality.

What about those Advanced Capabilities?

The slant bed lathe is a great design. Kent USA made it even better. For example, the “SM” in the KLR-series just mentioned stands for “sub spindle” and “milling.” That means these versatile machines can mill prismatic shapes that once needed a trip to the machining center. These include cross-holes, slots and flats, and even cam shapes and other non-round part profiles. Shops that want to take this concept even further can upgrade to a Y-axis turn/mill lathe, such as Kent USA’s KLM-300SY. It can machine practically any part or part feature that fits within its axis travels. Advanced machinery like this is changing the way shops process parts. Since secondary operations are unnecessary, tying up valuable cash in work-in-process becomes a thing of the past. Milling fixtures are eliminated. So are additional setups. And because it’s now possible to complete parts in a single operation, geometric part accuracy is greatly improved.

Dressing Up

A slant bed lathe with mill-turn capabilities is a no-brainer for any shop that wants to pull ahead of the competition. However, those willing to make the leap into modern CNC machining should consider taking them even further. For instance, options like a parts conveyor and auto door are a first step towards automation. So is an air blast, which assures that a robot can seat parts properly. A Renishaw tool setter helps reduce setup time. Oil mist collectors keep shop air clean. Sump skimmers extend coolant life. High-pressure coolant (HPC) significantly increases throughput. Add it all up, and you’ll see why shops everywhere are moving to turn/mill centers and multitasking lathes. Those who’ve bought one will tell you they’re the best thing since carbide.