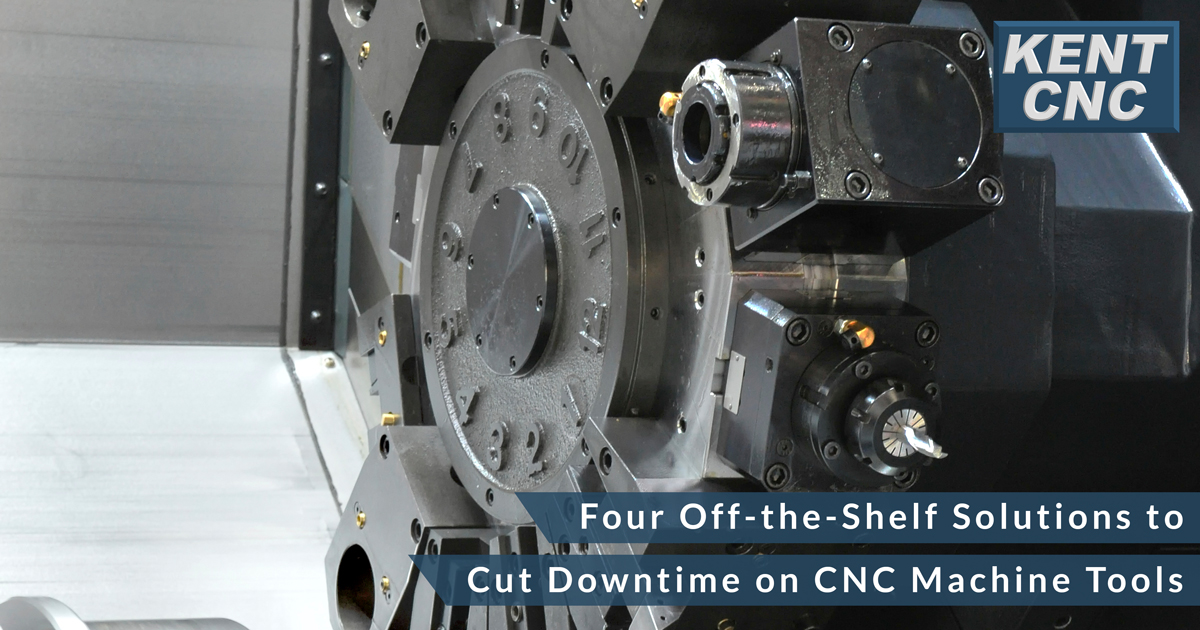

Quick-Change Tooling: Four Off-the-Shelf Solutions to Cut Downtime on CNC Machine Tools

Spending a few hours or even an entire shift setting up a CNC machine tool was once considered no big deal. Not anymore. With job quantities dropping and shops under increased pressure to reduce costs, setup time is critical. Of all the continuous improvement opportunities available to shops these days, increasing machine availability ranks among the most important. It’s also one of the easiest. The best way to do it? Quick-change tooling. If you own a Kent CNC KLR 2-Axis Horizontal Turning Series CNC lathe or KVR Linear Way VMC Series machining center (or even a competing brand), here are some ideas to get you started.

Quick-Change with Kennametal

To be clear, Kent CNC doesn’t promote or endorse any tooling brand . Plenty of high-quality options exist, most of which will help your Kent CNC perform to its maximum potential. That said, most machinists and shop owners have at least heard of Kennametal Inc., which introduced its KM quick-change system more than three decades ago. KM uses a set of ball bearings inside the toolholder base to expand a tapered sleeve. This draws the toolholder against the face of a quick-change mounting block or adapter to generate high-precision, dual-contact seating.

Sandvik Coromant Quick-Change

Competitor Sandvik Coromant launched its Capto brand of quick-change tooling in 1990. It also has a locating taper, but one that’s triangular in shape, or “lobed.” This is why many manufacturers refer to Capto as polygon shank tooling, or PSC. Like KM, Capto is a dual-contact interface. Both systems are extremely rigid and accurate. Either can be used on lathes or machining centers. There are universal tool blocks available, as well as TACU (Kennametal) and MACU (Coromant) turret adapting units. Both systems offer gazillions of milling adapters, boring bars, ER collets, and more. Both are excellent ways to reduce setup and tool change times.

Other, less well-known brands are available. Much of the smaller quick-change tooling available for these machines will work on a CNC lathe, or even a machining center. There’s the GenSwiss brand of quick-change ER adapters. TM Smith makes a similar system. I’m sure there are others out there, as well as plenty of home-grown solutions. Have an idea for shaving minutes and hours off your setup time? Let us know.