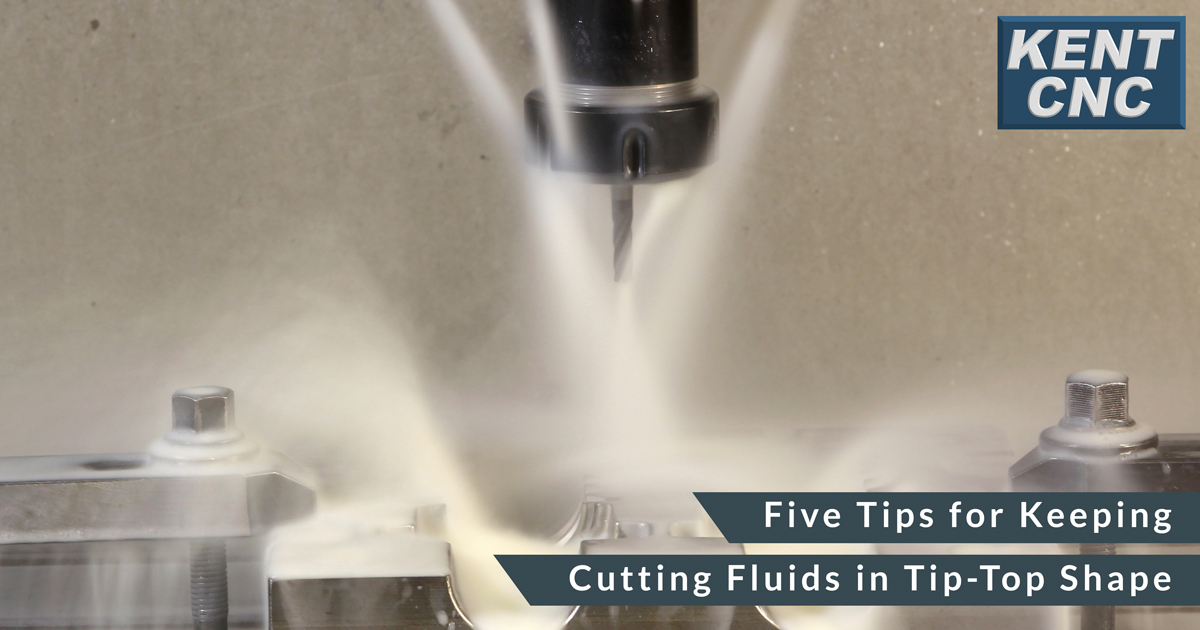

Five Tips for Keeping Cutting Fluids in Tip-Top Shape

Nobody likes a stinky machine tool. When cutting fluids are poorly maintained, anaerobic bacteria blossoms, feeding on the way lube and other unavoidable contaminants that collect within any machine sump. This is why Kent CNC’s KVR-series vertical machining centers are equipped with automatic coolant tank skimmers and enhanced chip flow capabilities, so that tramp oils are removed before they can become food for hungry microorganisms.

Don’t have a skimmer? That’s okay. Aftermarket ones are widely available. Installation takes minutes, and they are the best defense against nasty cutting fluids. For best results, be sure to let skimmers run periodically overnight and on weekends, after the sump has had a chance to settle.

Here are a few more pointers to get you started

- For machines equipped with high-pressure coolant (HPC) systems (standard on all KVR-series vertical machining centers), a filtration unit should be installed, as the small metal fines that would otherwise accumulate are tough on pump bearings—for that that matter, they’re also tough on paint, parts, seals, and cutting tools, so if you can afford one, filtration is a great idea no matter what coolant pressure you’re running.

- There’s more to good cutting fluid maintenance routines than skimming, however. If you don’t already have one, pick up a Brix-style refractometer from your machining supply company. They cost a couple hundred bucks, maybe a bit more for a digital version. Drop a little cutting fluid on the screen once a week, peek through the eyepiece, and you’ll soon know the exact ratio of cutting fluid concentrate to water. A little math calculation based on that result will tell you what strength makeup fluid is needed to attain target levels.

- It’s also a good idea to keep an eye on PH, and follow the coolant supplier’s recommendations on how to achieve proper acidity (or lack thereof). Also, use water from a deionizer or reverse osmosis systems whenever possible, otherwise most city tap water is fine. Just don’t use softened water, unless otherwise instructed by your coolant supplier

- No matter how well-maintained your cutting fluid, the day will come when it no longer works all that well. Time to clean the machine. You might break out a shovel, the Shop Vac, some floor dry and a bundle of rags, but a better idea is to invest in a Sump Doc or equivalent, a portable machine that makes sump cleaning fast and easy. Some even come equipped with internal filtration systems, allowing you to clean and refresh your coolant, extending its life.

Lastly, always consult with your machine tool manufacturer on which cutting fluids to use, and why. This is why Kent CNC Machine Tools has a staff of trained applications and sales engineers available to answer questions about how to best maintain cutting fluids on any of its KLR-series and KLM live-tool CNC lathes, its KMH auto-pallet horizontals, or KVTC traveling column VMCs. Between their advice and a well-executed maintenance plan, Monday morning stink will be a thing of the past.