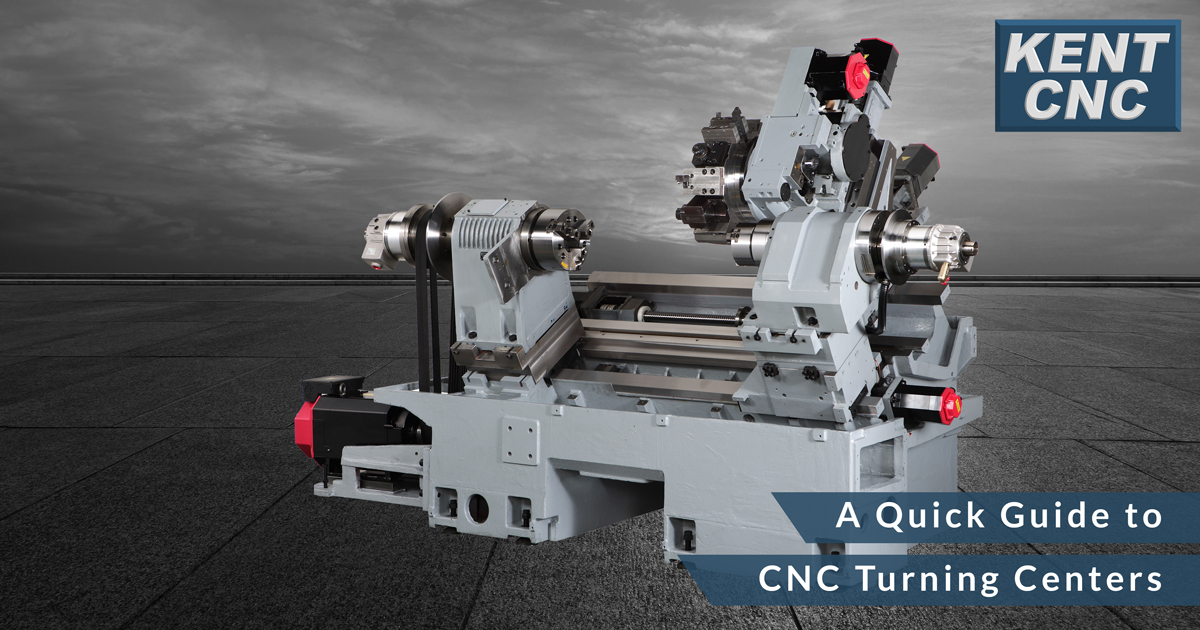

A Quick Guide to CNC Turning Centers

You can trace the history of the lathe’s origin as far back as 1300 B.C. as it was used by ancient civilizations like the Egyptians, Assyrians, and the Greeks. Over the centuries, we have seen the lathe evolve from a two-person, bow-driven machine during ancient times to its wide adoption and popularity during the Industrial Revolution, and now to the sophisticated precision CNC (Computer Numerical Control) turning machines we have today.

The Nuts & Bolts of Lathes

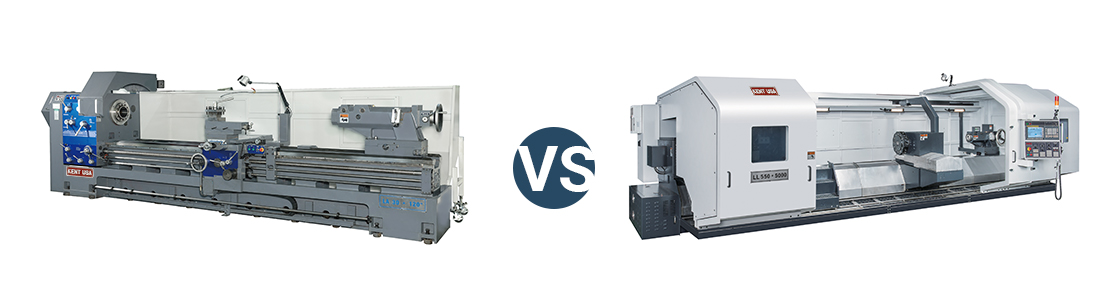

The difference between lathes and turning centers

For the most part, lathes today are commonly referred to as CNC lathes and CNC turning centers. The CNC lathe is a simpler 2-axis (X and Z-axis) machine that is computer-controlled and generally has one spindle. They are commonly flat-bed type and may have only minimal protective enclosure around the machine and the machine ways.

CNC turning centers are also computer controlled but are more powerful and can have 3, 4 or 5-axes with more versatile capabilities and applications such as turning, drilling, tapping, and milling using live tools with powered rotary tool turret, sub-spindle (dual spindles), Y-axis, and multiple turrets. They are usually slant-bed type and have full machine enclosures to keep chips and coolant splashes within the machine. CNC turning centers have higher production capabilities than CNC lathes.

Lathe Components

Here are some of the most important parts of a CNC Lathe:

The Headstock

The headstock serves as the housing for the main spindle where the jaw chuck is attached which holds the workpiece. The spindle bore or bar capacity determines the maximum diameter of a workpiece that can be mounted thru the head stock. The headstock is normally located on the left side of the lathe.

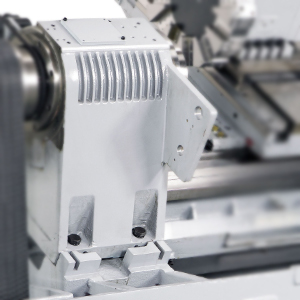

The Tailstock

The tailstock is mounted on the bed of the lathe, opposite the headstock and slides along it in alignment with the headstock Z-axis. The primary function of the tailstock is to provide support to the workpiece being machined between centers. The tailstock has a quill with a taper to hold tooling. CNC turning centers with sub-spindles (or dual spindles) will have a second spindle in lieu of a tailstock. The sub-spindle can move in the Z-axis longitudinally toward the main spindle under CNC control. Sub-spindle enables the machining of the back-side of a workpiece without additional operator loading/unloading in the work process.

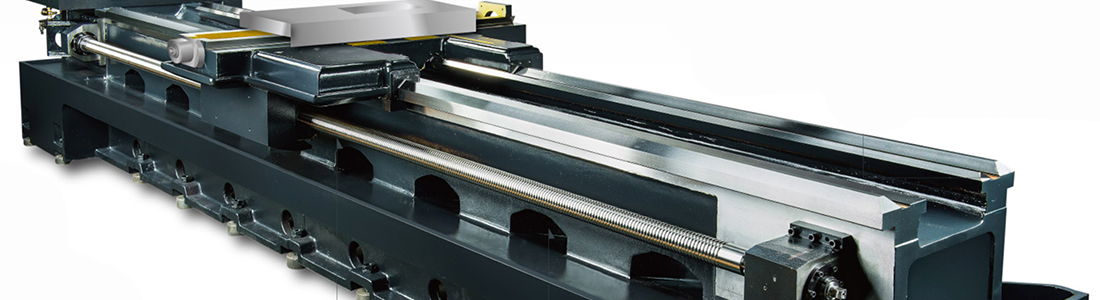

The Bed

The bed, commonly made of cast iron, is the base where various fixed and operational parts are mounted. It is connected to the headstock and spans the distance from the headstock to the tailstock. It is positioned under the workspace. Tool turret and various attachments ride along the rails or ways of the bed, across the length of it. Linear guideways are better suited for higher rapids traverse and machining of abrasive materials. Solid box ways are better suited for heavier or interruptive cuts with better tool rigidity.

The Carriage

The carriage supports the cutting tool turret, guiding and feeding it against the workpiece. The main parts consist of the saddle, cross-slide, and turret. Turning centers with live tool turrets can have powered rotary tools for milling operations which greatly increases the capabilities of the machine and can reduce or eliminate second operations on workpieces.

When is a Lathe Considered a CNC Turning Center?

While there is no hard and fast rule for making this distinction, a reasonable expectation for a CNC turning center commonly starts with a full machine enclosure. Next, the bed ways for the tailstock and carriage are separate sets which allows the tailstock and steady rests to be positioned as needed without interfering with the carriage and tool turret travels across the full length of the bed. In many cases, the position of the tailstock body can be programmed under CNC control.

Turning Center Configurations (Horizontal or Vertical)

There are two types of CNC turning centers: horizontal and vertical. Horizontal turning centers are the most common. Vertical turning centers are typically called a vertical turret lathe or VTL. With a horizontal turning center, the spindle is horizontally oriented, and tools are mounted out of the side of tool holder and cut across the workpiece. With this type of turning center, gravity pulls the chips away from the workpiece.

The CNC vertical turning center is virtually the same as the CNC horizontal turning center but is upended, allowing the headstock to sit on the floor and the faceplate to become a horizontal rotating table. This is beneficial for machining large, heavy and short workpieces. In this case, gravity contributes to seating the workpiece into the work holding. However, chips may become a problem as gravity does not necessarily help chip evacuation from the workpiece. An inverted vertical turning center is like the afore mentioned but reverses the position of the spindle and jaw chuck.

Turning Uses and Applications

Aerospace, automotive, medical, oil and gas, etc. are some of the industries where CNC turning centers are utilized. These machines do particularly well with machining round metal parts, bars, tubes, gears, etc. Multitasking is the word that best describes live tools powered turrets. Live tooling allows the lathe to mill, drill, bore, turn, and tap workpieces. The benefit is reduced work-process time, which increases your productivity and profitability. Kent CNC offers a full range of CNC Turning Centers with live tooling, dual spindles, Y-axis, multiple turrets, and robot tending to meet simple to complex machining applications and solutions.

Automating your CNC Turning Center

Automated CNC turning center solutions are also available for even more productivity.